How to manufacture of the trailer ?

Let’s discuss the manufacturing process of trailer. Thus, after getting the drawing set in your hands, you can start the work of building the trailer. If you are going to build the trailer yourself, you must have basic facilities, equipment and knowledge of manufacturing methods. They are,

- Knowledge of metal cutting

- Knowledge of measurements and tolerances

- Welding knowledge

- Knowledge of handling power tools like drills, grinders etc.

- Basic electrical knowledge

Apart from that, there should be a suitable space or a workshop with basic facilities make your trailer. If you don't have the above mentioned facilities or skills, hiring a workshop that has the potential would be the next best solution.

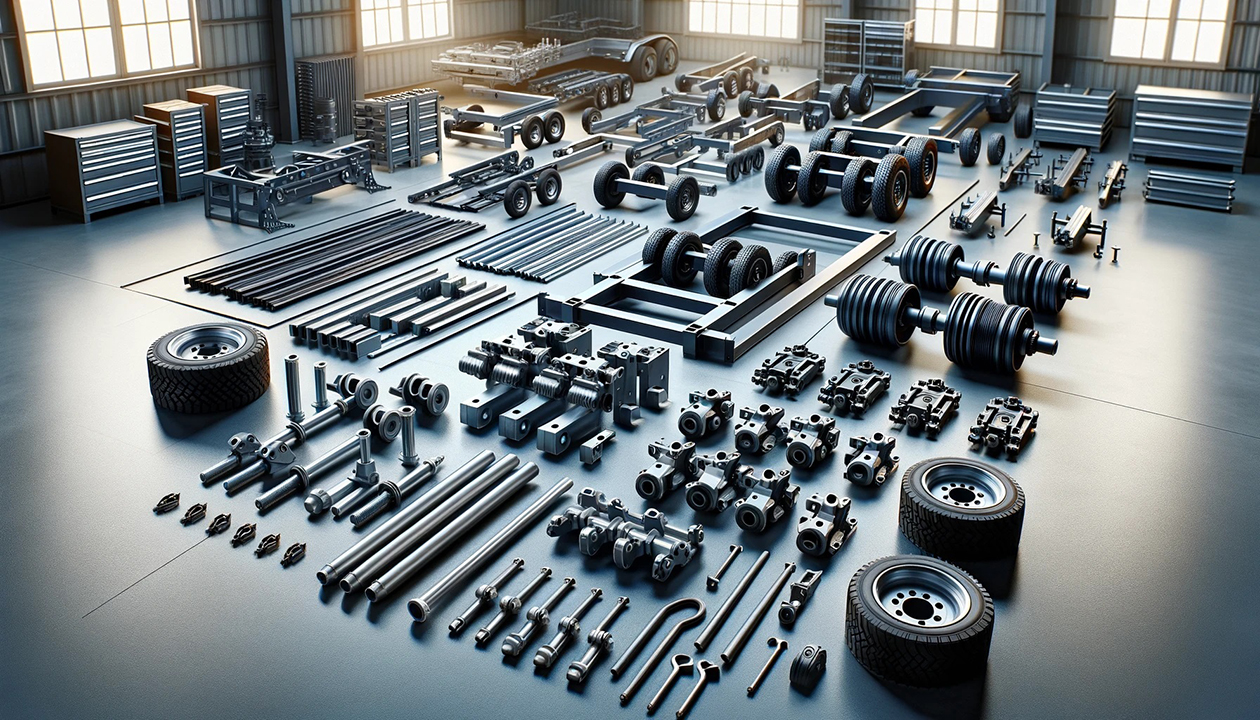

Whatever above method that you are going to follow , the next thing to do is to procure the materials needed for the trailer. Whether you are making the frame from steel or aluminum, according to the design you have prepared, get the box bars, C channels, angle irons in the relevant sizes and in the relevant quantities. Then according to the design, buy the axle suspension set, jockey wheel or landing leg, tow coupling, rims and tires, brake system components, electrical system components etc.

Below is a list of the tools you need.

- Measuring tape

- Pencil or marker pen

- Angle grinder with cutting wheels and grinding wheels

- Welding plant and welding rods

- Hand drill

- L-Square Angle Ruler

- Combination wrench set

- Hammer

- Clamps

- Equipment for painting ( Air compressor and spray nozzles or spray painting cans )

- Wire cutter

- Screw driver set

Now you can start the work of building the trailer.

First, get all of part drawings. make all the individual parts accordingly. Before cutting the material, plan to cut the metal bars to maximize utilization and minimize waste. Such box bars and C channels are often commercially available in 6 m (20 ft) lengths. If there are parts to be cut from metal sheet or metal plate, it is more appropriate to outsource and cut them from a CNC workshop. For that you need to bring the .DXF file or .DWG files of the relevant parts. If there are bends in the sheet metal parts, take the development drawings.

After all the individual parts are made according to part drawings, make the sub assemblies according to relevant assembly drawings. After all the relevant sub-assemblies are made, you can assemble the complete trailer frame using the parts and assemblies you created. Then connect the suspensions, axles, wheels to the trailer frame. Join Tow coupling and Jockey Wheel. A hydraulic jack is required to lift the trailer when the axles are connected. Or preferably a small overhead crane. Now you have set up the trailer frame and attached the trailer parts including the axles and suspensions.

Next task is painting.

First remove any corrosion if there on the trailer. Then apply a suitable metal primer first. Then paint with a color of your choice. A total ink thickness of about 100 microns is sufficient. After the paint dries well, connect the brake and electrical components.

Now you have completed your trailer. Now you can connect the trailer to the vehicle and check it out. Here, first check if the brake lights, signal lights are whether working properly. Then drive slowly for a short distance and check the brakes. This way your trailer dream can become a reality.